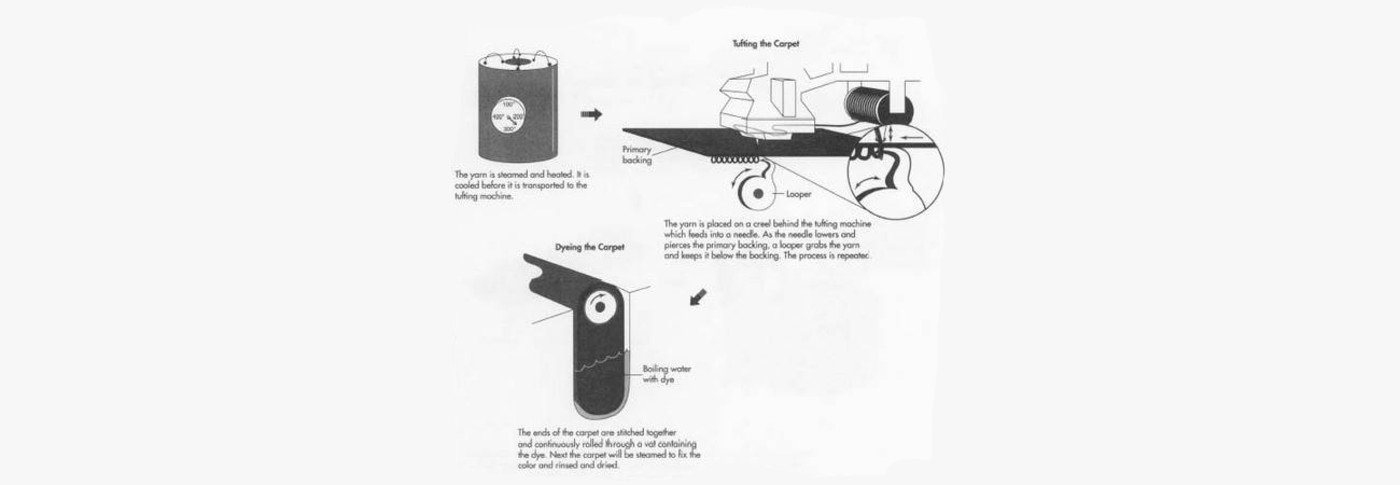

The effect of the process gives fibers yarns or fabric dimensional stability and very often other desirable attributes like higher volume wrinkle resistance or temperature resistance.

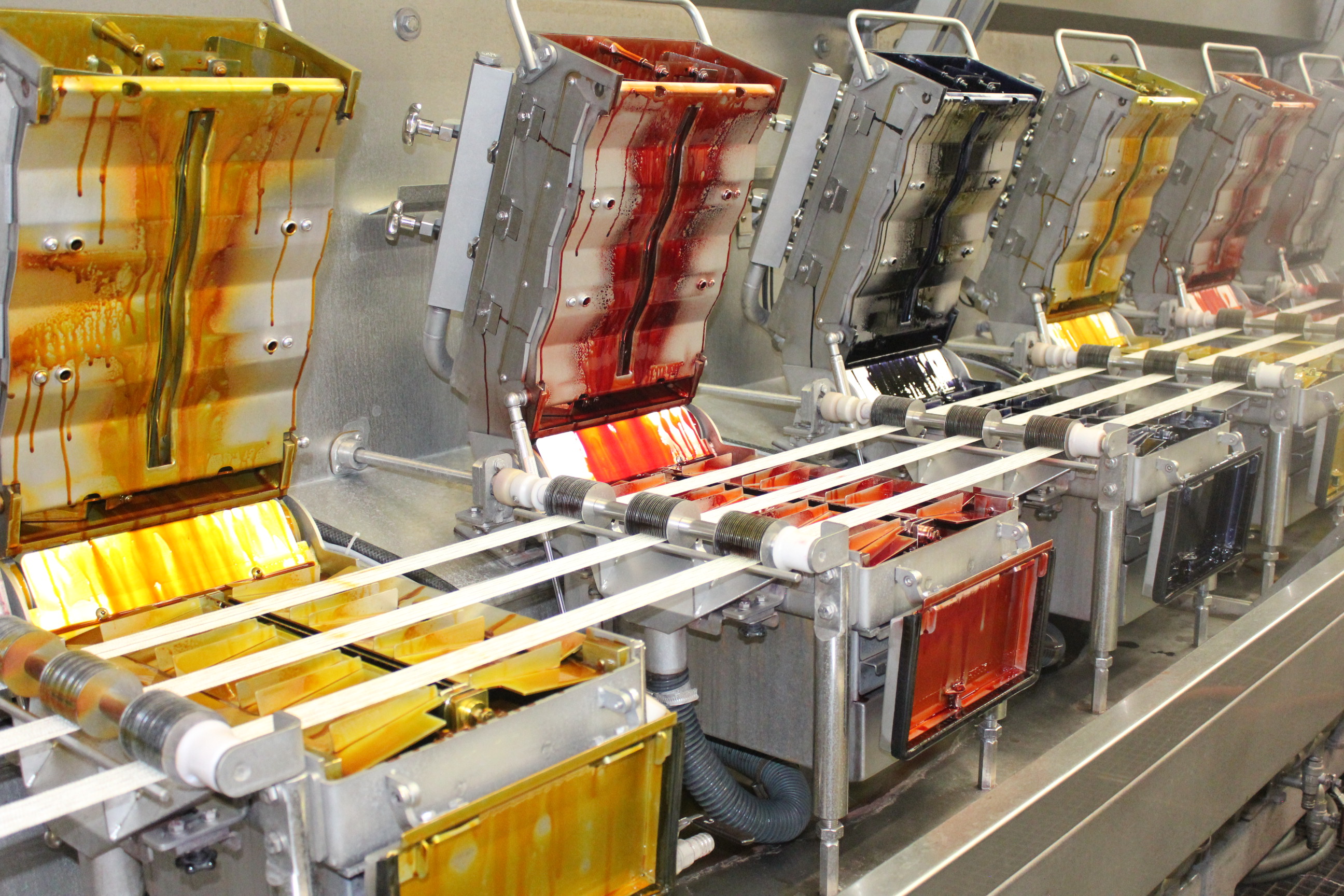

Carpet fiber heat setting machine.

Take up winder to builds final package of yarn duly bulked and heat sated ready for tufting carpet up to capacity of 4 kgs.

The effect of this process gives fibers yarns or fabric.

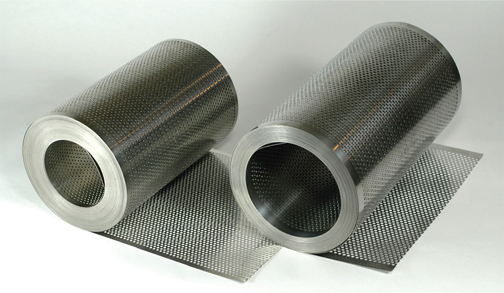

Belts for carpet yarn processing.

Power heat set gmbh has been supplying the carpet industry with machines and components for carpet yarn treatment for over 40 years.

The dollfus muller belts can be either in kevlar or fibre glass in order to work at 200 c.

The stage of heat setting depends on extent of contaminations and types of fibres or yams present in the fabric.

Very often heat setting is also used to improve.

Stenter machine stenters are widely used for stretching drying heat setting and finishing of fabrics.

Heat setting after dyeing could lead to the sublimation of disperse dyes if not accurately selected.

Dollfus muller manufactures open mesh transport belts for heat setting the carpet yarn in suessen power heat set machines.

The machines are manufactured in germany by highly qualified technicians and offer proven reliability flexibility and productivity in continuous heatsetting.

There are many natural materials but only several that are commonly used in carpet.

Heat setting is a term used in the textile industry to describe a thermal process.

Other natural fibers are more often made into area rugs including sisal cotton seagrass jute silk and coir.

Complete controlling of heat set process is done by plc controlled yarn sensing yarn speed dwell time chamber temperature yarn speed at take up in synchronizing ways to achieve desired uniform yarn bulking and heat setting.